Grinder Teeth Types: Diamond vs Pyramid Technical Guide

Grinder Teeth Types: Diamond vs Pyramid Technical Comparison Guide

Grinder tooth geometry dramatically impacts grinding performance, consistency, durability, and customer satisfaction - yet remains one of the most overlooked specifications in cannabis accessories. Understanding the mechanical differences between diamond-shaped teeth, pyramid teeth, and alternative patterns helps dispensaries stock optimal grinder selections while educating customers on functionality that justifies premium pricing over commodity alternatives.

This technical analysis examines how tooth shape affects grinding mechanics, material flow, consistency, and long-term wear patterns across different grinder materials and price points. Whether you're a dispensary buyer evaluating wholesale grinder options or a customer seeking to understand what makes premium grinders perform better, this guide provides engineering-based insights into the most critical but least understood grinder specification.

Grinder Tooth Geometry Fundamentals: How Shape Affects Function

Tooth shape determines how grinders interact with flower structure, how material flows through grinding chambers, and how consistently the final product achieves desired texture. Understanding these mechanical principles helps predict grinder performance from visual inspection alone.

The Shearing vs Crushing Principle: Effective grinders shear plant material by creating opposing cutting edges that slice through flower structure, similar to scissors. Crushing-dominant designs mash material rather than cutting cleanly, resulting in inconsistent texture and excessive pulverization of trichomes. Tooth geometry determines whether grinders primarily shear (optimal) or crush (problematic) during operation.

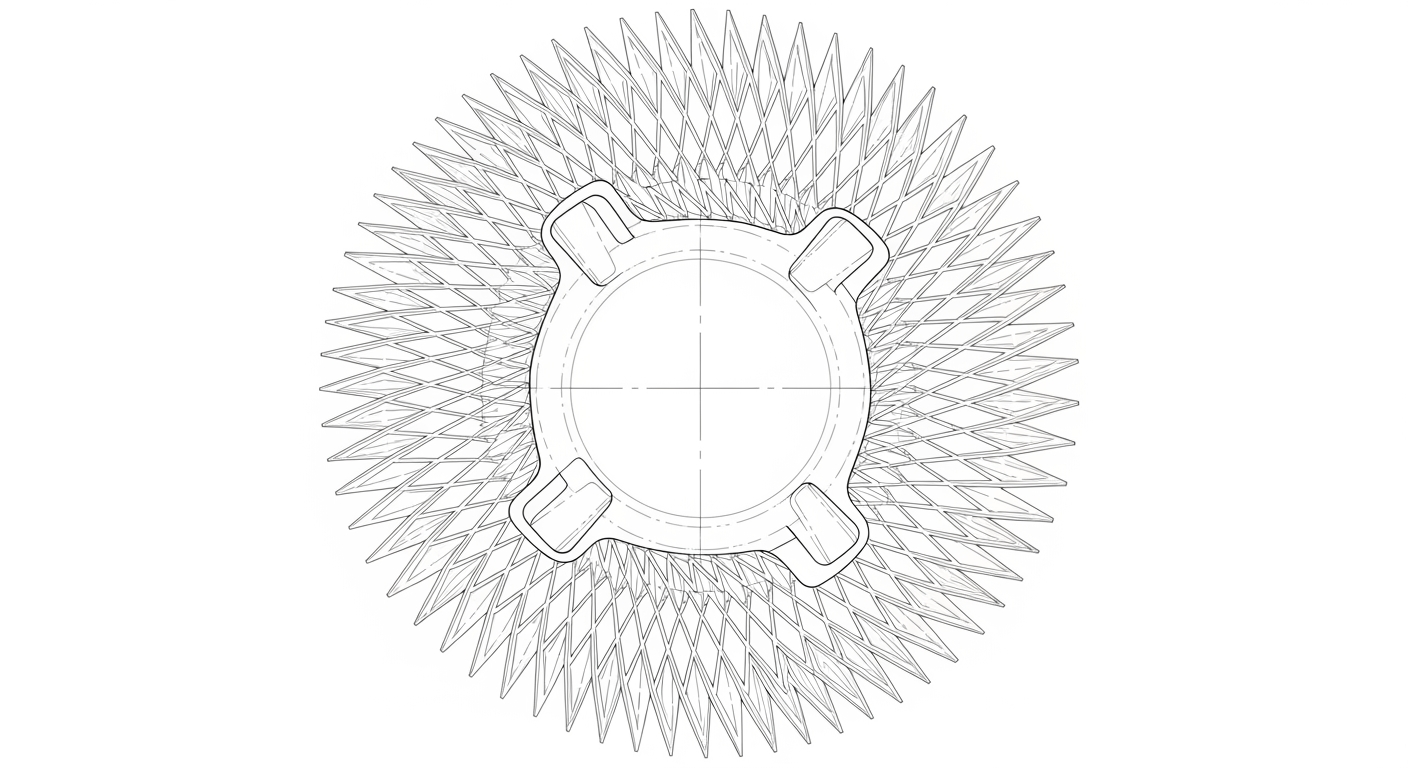

Material Flow and Chamber Dynamics: As grinder halves rotate opposite directions, teeth must efficiently move ground material away from cutting zones toward chamber edges where it falls through holes into collection areas. Poor tooth geometry creates dead zones where material accumulates rather than flowing properly. Premium custom grinders optimize tooth patterns specifically for material flow efficiency.

Edge Retention and Wear Patterns: Different tooth geometries concentrate cutting forces differently, affecting how quickly cutting edges dull through use. Sharp-angled teeth may cut aggressively initially but dull faster than gradual-angle designs. Understanding wear patterns helps dispensaries set appropriate customer expectations about grinder lifespan and performance degradation over time.

Number of Teeth vs Tooth Shape Interaction: Tooth count and tooth geometry work together determining grinding character. Many small teeth with aggressive geometry over-pulverize material, while few large teeth with shallow geometry produce coarse, inconsistent results. Optimal grinders balance tooth count with appropriate geometry for desired output texture.

Diamond-Shaped Teeth: Design Characteristics and Performance Profile

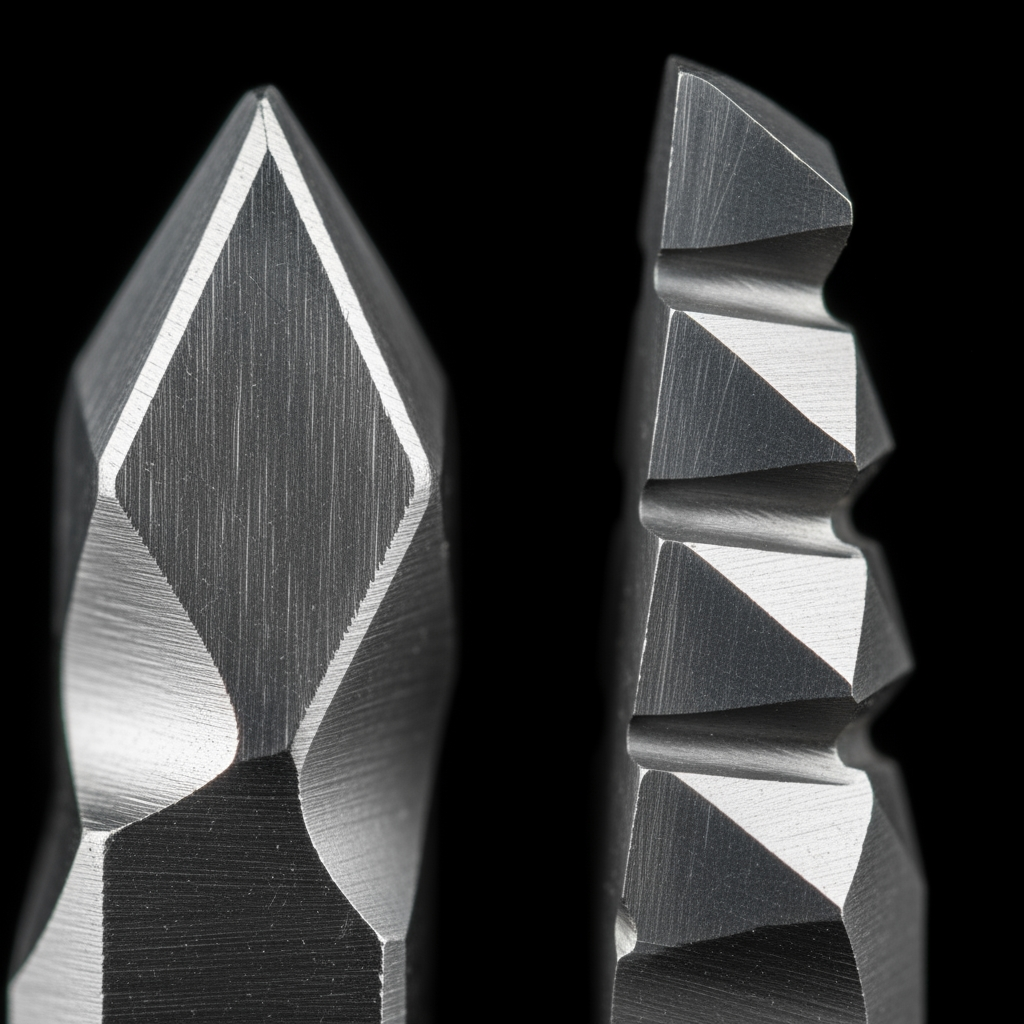

Diamond-pattern teeth represent the most common premium grinder design, featuring four-sided pointed teeth arranged in offset rows. Understanding why this pattern dominates high-end grinders helps justify premium pricing to customers questioning cost differences.

Geometry and Cutting Mechanics: Diamond teeth feature approximately 60-90 degree included angles at points, creating aggressive cutting edges that efficiently shear through flower structure. The four cutting faces per tooth provide multiple engagement angles as grinder halves rotate, ensuring material encounters cutting edges regardless of orientation. This multi-directional cutting capability produces consistent results even with loosely-loaded grinders.

Material Flow Characteristics: The pointed diamond shape pushes ground material outward toward chamber walls as teeth rotate, creating efficient flow away from cutting zones. This self-clearing behavior prevents clogging and maintains consistent grinding action even when processing sticky, resinous flowers. Dispensaries serving customers who primarily consume high-resin strains should prioritize diamond-tooth grinders for optimal performance.

Consistency and Output Texture: Diamond teeth excel at producing medium-fine, consistent grind texture ideal for rolling and vaping. The aggressive cutting action fully processes flower without requiring excessive rotation cycles. Most users achieve desired consistency in 5-8 rotations with diamond-tooth grinders versus 10-15 rotations with less efficient geometries.

Durability Considerations: The pointed diamond geometry concentrates cutting forces at relatively small contact areas, which can accelerate wear in softer aluminum alloys. However, premium aluminum alloys and harder metals (titanium, stainless steel) maintain diamond tooth sharpness through thousands of grinding cycles. Budget diamond-tooth grinders using soft aluminum may show noticeable dulling after 6-12 months of daily use, while premium materials maintain performance for years.

Pyramid (Triangular) Teeth: Alternative Geometry Performance Analysis

Pyramid or triangular teeth feature three-sided pointed design offering distinct performance characteristics compared to diamond patterns. Understanding these differences helps dispensaries match grinder types to specific customer needs and preferences.

Structural Geometry and Strength: Pyramid teeth with three cutting faces rather than four create slightly wider angle at points (typically 75-100 degrees versus 60-90 for diamond). This geometry provides greater structural strength and resistance to bending or breaking, particularly important in larger teeth designs. Large capacity grinders often employ pyramid teeth for improved durability under high-volume use.

Cutting Efficiency Comparison: Pyramid teeth generally cut slightly less aggressively than diamond equivalents due to wider point angles and fewer cutting faces. This produces somewhat coarser grind texture that some users prefer for specific consumption methods. Customers who prefer chunkier material for smoking (versus fine powder for vaping) often report satisfaction with pyramid-tooth performance characteristics.

Material Flow Patterns: The three-sided geometry creates different flow dynamics than diamond teeth, sometimes resulting in slightly longer grinding times to achieve equivalent texture. However, the simpler geometry is often easier to manufacture consistently, potentially providing better quality control in mid-priced grinders where manufacturing precision varies.

Maintenance and Cleaning Implications: Pyramid teeth with wider angles tend to accumulate slightly less residue in acute angles compared to sharper diamond points. This can translate to marginally easier cleaning and maintenance over long-term use. For customers who resist regular grinder cleaning, pyramid teeth may maintain performance slightly longer between cleanings.

Alternative Tooth Patterns: Specialty Designs and Performance Niches

Beyond standard diamond and pyramid geometries, specialty tooth patterns serve specific performance objectives or aesthetic preferences. Understanding these alternatives helps dispensaries offer comprehensive selections for diverse customer needs.

Straight-Pin or Cylindrical Teeth: Some grinders employ simple cylindrical posts rather than pointed teeth. These designs crush more than shear, typically producing less consistent results. However, their extreme simplicity makes them virtually indestructible and very easy to clean. These appear primarily in budget grinders where manufacturing cost minimization outweighs performance optimization.

Shark Tooth or Serrated Patterns: Aggressive serrated edges incorporate multiple small cutting points along each tooth face, creating cheese-grater-like surfaces. These excel at processing extremely dense or sticky material but may over-pulverize dry flower. Serrated patterns serve niche applications like hash and concentrate processing better than general flower grinding.

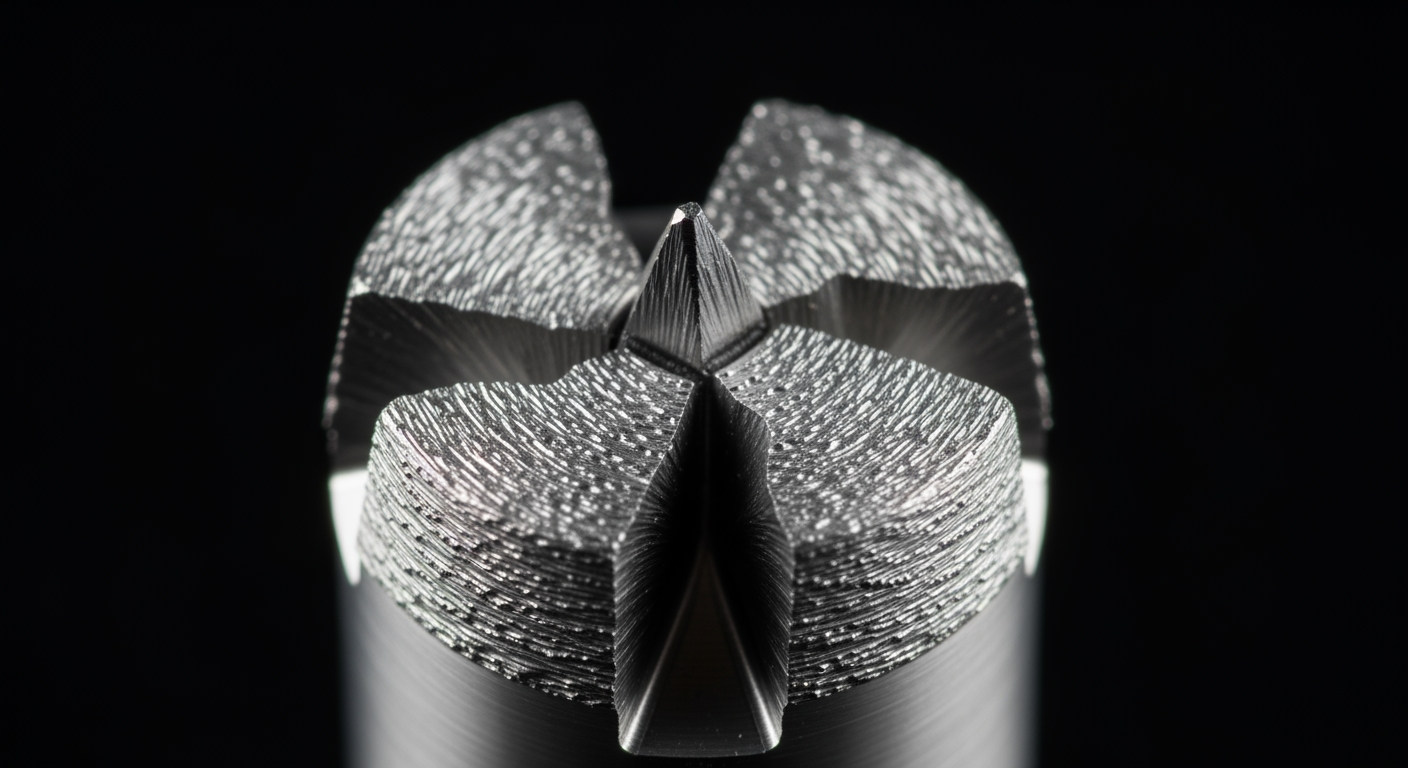

Hybrid Multi-Stage Designs: Premium grinders sometimes incorporate different tooth geometries in upper versus lower chambers, creating two-stage grinding process. Aggressive first-stage teeth break down flower structure, then finer second-stage teeth process material to final consistency. These complex designs command premium pricing but deliver exceptional consistency. Customers willing to invest in top-tier grinders appreciate the performance differences hybrid systems provide.

Rectangular or Flat-Top Teeth: Some manufacturers employ teeth with flat tops rather than points, relying on sharp corner edges for cutting action. These designs prioritize durability over cutting aggression and appear most commonly in metal grinders intended for extremely heavy use. While functional, flat-top teeth generally require more rotations to achieve desired consistency compared to pointed alternatives.

Material and Tooth Geometry Interactions: Aluminum vs Steel vs Titanium

Tooth pattern performance varies significantly based on grinder material - the same tooth geometry in different metals produces different cutting characteristics, durability, and long-term performance.

Aluminum Diamond Teeth Performance: Aluminum's relatively soft material properties mean diamond teeth in aluminum grinders dull somewhat faster than harder metals, particularly at the sharp points experiencing highest contact pressure. Anodized surface treatments help, but aluminum diamond teeth eventually round over with heavy use. Budget aluminum grinders show noticeable performance degradation after 6-12 months daily use, while premium aluminum alloys extend this to 18-24+ months. Customers should understand this tradeoff - aluminum provides lightweight, affordable grinders but not lifetime durability.

Stainless Steel Tooth Longevity: Steel's hardness maintains tooth geometry through thousands of grinding cycles with minimal dulling. Diamond teeth in quality stainless steel grinders effectively last indefinitely for normal consumer use. The tradeoff comes in weight - steel grinders feel substantially heavier than aluminum equivalents. Customers prioritizing long-term performance over portability appreciate steel's durability advantages.

Titanium Premium Performance: Medical-grade titanium combines exceptional hardness with lightweight properties, delivering optimal tooth edge retention in minimal weight packages. Titanium diamond teeth maintain factory-sharp cutting performance through multi-year daily use. The premium pricing (typically 2-3X aluminum equivalents) reflects both material cost and manufacturing difficulty, but serious enthusiasts consider the performance and lifespan worth the investment. Dispensaries serving high-end customer segments should stock at least one premium titanium option for customers wanting absolute best performance.

Acrylic and Plastic Tooth Limitations: Budget grinders using plastic or acrylic materials simply cannot maintain meaningful tooth geometry under use. Plastic teeth deform, dull, and eventually break regardless of geometric design. These belong exclusively in ultra-budget tier where customers prioritize minimum upfront cost over performance or longevity. Dispensaries should set appropriate expectations - plastic grinders are temporary solutions, not long-term investments.

Tooth Count and Density: Finding Optimal Balance for Different Applications

Tooth count interacts with geometry determining grinding character, speed, and final texture. Understanding these relationships helps match grinders to customer usage patterns and preferences.

High Tooth Density (40-60+ teeth): Many small teeth create fine, powdery grind texture through numerous small cutting actions. These excel for vaporizer users who need very fine, consistent particle size for optimal airflow and even heating. However, high tooth counts increase surface area where residue accumulates, requiring more frequent cleaning. Heavy users processing sticky material may find high-tooth-count grinders become gunked and difficult to operate faster than moderate tooth density alternatives.

Moderate Tooth Density (25-40 teeth): This range represents optimal balance for most users - enough teeth for consistent results without excessive surface area accumulating residue. Medium tooth counts work well across diverse flower moisture levels and resin contents. Dispensaries should stock majority of 4-piece grinder selections in this range to serve broadest customer base effectively.

Low Tooth Density (15-25 teeth): Fewer, larger teeth produce coarser grind texture and require more rotation cycles achieving fine consistency. However, reduced surface area means less frequent cleaning needs and easier maintenance. Customers who prefer chunky material for smoking and resist regular grinder cleaning appreciate lower tooth counts that maintain functionality longer between cleanings.

Size-Appropriate Tooth Density: Small grinders (1.5-2 inch diameter) function best with lower absolute tooth counts (20-30) to maintain adequate spacing. Large grinders (2.5+ inch diameter) require higher tooth counts (40-60+) to fully utilize chamber volume. Evaluate tooth density relative to grinder size rather than absolute numbers - a 50-tooth pattern works excellently in a 2.5-inch grinder but creates problematic crowding in a 2-inch model.

Customer Education: Explaining Tooth Geometry Value Propositions

Most customers don't understand grinder tooth geometry and need education connecting design features to practical performance benefits. Training dispensary staff to explain these concepts builds value justification for premium products while demonstrating product expertise.

Visual Comparison Demonstrations: Keep sample grinders with different tooth patterns behind counter for customer examination. Let customers feel tooth sharpness differences and observe geometric variations while explaining how these impact performance. Physical demonstration converts abstract concepts into tangible understanding that justifies price differences.

Performance-Based Language vs Technical Jargon: Instead of "diamond teeth feature 65-degree included angles with four cutting faces," explain "these pointed diamond-shaped teeth cut efficiently from multiple directions, so you get consistent results in fewer rotations and it works well even with sticky flower." Translate engineering concepts into practical benefits customers care about.

Material and Tooth Geometry Combined Value Story: Explain how premium materials maximize tooth geometry advantages: "This grinder uses diamond-shaped teeth in aircraft-grade aluminum, so the sharp points stay sharp through thousands of uses. Budget grinders with similar teeth use softer metal that dulls quickly, so they work well initially but performance degrades over months. The premium material ensures tooth design keeps working like new."

Matching Tooth Design to Usage Patterns: Ask customers how they consume cannabis and match tooth geometry to their needs: "Since you're primarily vaping, these fine diamond teeth will give you the powdery consistency vaporizers need. If you were mainly rolling joints, I'd show you options with slightly larger teeth that leave material a bit chunkier." Customized recommendations based on actual usage builds trust and increases satisfaction with purchases.

Quality Control: Evaluating Tooth Manufacturing Consistency

Tooth geometry quality varies dramatically between manufacturers. Dispensary buyers should evaluate these indicators when selecting wholesale grinder suppliers to ensure consistent customer satisfaction.

Tooth Uniformity Across Chamber: Examine whether all teeth in a grinder show consistent size, shape, and sharpness. Budget manufacturing often produces irregular teeth with some sharp, others dull, and varying heights. Premium grinders feature uniform teeth throughout - CNC machining or precision casting creates identical geometry across all teeth. Compare multiple units from a wholesale batch - if tooth quality varies unit-to-unit, expect customer complaints about inconsistent performance.

Sharp vs Rounded Edges: Run fingertip lightly across tooth points and edges (carefully to avoid cuts). Premium teeth feel sharp with distinct points and crisp edges. Budget alternatives often feature rounded, dull points even when brand new. Dull factory teeth indicate soft materials or poor machining that will only worsen with use. Any grinder with dull teeth when new should be rejected regardless of pricing - customer satisfaction will be poor.

Tooth Height Consistency: View grinder chamber from side angle and verify all teeth reach same height. Uneven tooth heights create inconsistent cutting action where short teeth don't engage material effectively. This manufacturing defect appears primarily in cheap cast grinders with poor quality control. Height consistency indicates precision manufacturing that typically correlates with overall quality.

Burrs, Flash, and Surface Finish: Examine teeth for casting burrs, metal flash, or rough surfaces from poor finishing. These defects create unpleasant user experience, accumulate residue rapidly, and indicate overall manufacturing quality problems. Quality grinders show smooth, clean tooth surfaces with crisp edges and no manufacturing artifacts. Don't accept "budget pricing means lower quality" - poorly finished teeth create safety concerns and customer dissatisfaction that damages dispensary reputation.

Tooth Geometry and Kief Collection: Screen Interaction Effects

Tooth design impacts not just grinding performance but also kief collection efficiency in multi-chamber grinders. Understanding these relationships helps set customer expectations and optimize product recommendations.

Fine vs Coarse Grind Impact on Trichome Separation: Aggressive tooth geometries that produce powdery grind also break more trichome heads during grinding process, reducing intact trichomes available for screen collection. Coarser tooth designs leave larger plant particles with more intact trichomes that separate effectively when shaken through screens. Customers maximizing kief collection may achieve better results with pyramid teeth or lower tooth densities versus ultra-fine diamond patterns.

Over-Grinding and Trichome Destruction: Extremely sharp, aggressive teeth can pulverize trichome heads into fine dust that passes through screens mixed with plant material rather than collecting as pure kief. This particularly affects grinders with very high tooth counts and aggressive angles. Educate customers that maximum grinding efficiency doesn't always equal maximum kief collection - moderate tooth aggression often produces better kief quantity and quality.

Grind Consistency and Screen Clogging: Inconsistent tooth geometry producing variable particle sizes leads to faster screen clogging as fine particles pack into mesh while larger pieces accumulate on top. Uniform teeth creating consistent grind texture reduce screen clogging and maintain kief collection efficiency longer between cleanings. This represents another reason to prioritize quality grinders with precision-manufactured teeth.

Material Flow and Kief Chamber Access: Some tooth patterns push ground material more efficiently toward chamber edges where it falls through holes to middle chamber, while poor designs create accumulation in center requiring manual material distribution. Efficient material flow means more flower passing across screens more quickly, improving kief collection. Diamond teeth generally excel at outward flow versus pyramid alternatives.

Premium Tooth Features: Advanced Designs Worth Higher Pricing

Top-tier grinders incorporate specialized tooth features justifying significant price premiums. Understanding these advanced designs helps dispensaries explain value propositions for luxury grinder segments.

Multi-Angle Cutting Edges: Some premium diamond teeth feature compound angles with primary and secondary bevels, creating progressively aggressive cutting action similar to quality knife designs. These complex geometries cost more to manufacture but deliver superior cutting performance and edge retention. Customers who appreciate fine craftsmanship and optimal performance respond well to detailed explanation of these engineering refinements.

Reinforced Tooth Bases: Premium grinders sometimes thicken tooth bases while maintaining sharp points, creating strength where teeth meet chamber floor. This prevents bending or breaking under high-torque grinding of dense material. The reinforced design requires more material and machining time but delivers durability justifying higher pricing for heavy-use customers.

Curved or Twisted Tooth Profiles: Advanced designs incorporate slight curves or twists in tooth geometry creating spiral cutting action as grinder rotates. This complex three-dimensional geometry improves material flow and reduces grinding effort. Manufacturing costs increase substantially for 3D tooth profiles, but performance benefits appeal to customers seeking absolute best grinding experience.

Opposing Chamber Tooth Patterns: Ultra-premium grinders sometimes employ different tooth geometries in top versus bottom chambers, with patterns designed to mesh optimally as chambers rotate. This creates shearing action superior to matching tooth patterns. The engineering and manufacturing precision required makes this approach appear only in highest-tier products, but the performance difference is demonstrably superior to conventional matching-tooth designs.

Tooth Wear and Performance Degradation: Setting Customer Expectations

All grinder teeth eventually dull through use. Honest education about performance lifespan and degradation patterns builds realistic expectations preventing customer disappointment.

Typical Aluminum Tooth Lifespan: Quality aluminum grinders with diamond teeth maintain optimal performance for 12-24 months with daily use (grinding 0.5-1+ grams per day). Budget aluminum may show noticeable dulling after 6-9 months. This doesn't mean grinders stop working - cutting efficiency gradually decreases requiring more rotations for equivalent results. Set expectations that aluminum grinders are consumable items lasting 1-2+ years depending on quality and usage intensity.

Steel and Titanium Extended Performance: Premium metal grinders maintain essentially factory-fresh cutting performance for 3-5+ years even with heavy daily use. Tooth dulling occurs so gradually that users typically don't notice degradation. This longevity justifies 2-3X pricing versus aluminum - total cost of ownership over 5 years actually favors one premium grinder versus multiple aluminum replacements. Make this value calculation explicit for customers comparing prices.

Usage Pattern Impact on Wear Rates: Processing extremely dry flower accelerates tooth wear more than typical moisture levels due to increased abrasion. Very sticky, resinous material creates more buildup but less actual wear. Customers grinding large quantities daily will see faster tooth dulling than occasional users regardless of material. Ask about usage patterns when recommending grinders to match durability to expected lifespan needs.

Maintenance Extends Tooth Performance: Regular cleaning prevents hardened residue buildup that makes teeth work less efficiently. Clean teeth cut better and experience less wear than residue-coated equivalents. Educate customers that proper maintenance significantly extends effective grinder lifespan regardless of tooth geometry or material. Dispensaries should stock and recommend cleaning supplies alongside grinder sales, positioning maintenance as performance investment rather than just upkeep chore.

Conclusion: Tooth Geometry as Grinder Performance Differentiator

Grinder tooth design represents the single most important performance specification, yet remains poorly understood by most consumers and many retailers. Dispensaries that develop staff expertise in tooth geometry create competitive differentiation through educated product recommendations that match customers to optimal solutions rather than just pushing highest-margin products.

Diamond teeth excel for most applications through efficient multi-directional cutting and excellent material flow. Pyramid teeth offer enhanced durability and slightly coarser grind appealing to specific preferences. Premium materials maximize any tooth geometry's performance and longevity, while budget materials limit even excellent designs' long-term effectiveness.

Success in grinder merchandising requires translating these technical concepts into customer-relevant language emphasizing practical benefits - consistency, efficiency, durability, and maintenance ease - that justify premium pricing while ensuring customer satisfaction through appropriate product-to-need matching.

Ready to stock grinders with optimized tooth geometry delivering superior customer satisfaction? Explore MunchMakers' complete grinder collections featuring precision-manufactured diamond and pyramid teeth in aluminum, steel, and titanium across all price points for comprehensive customer segment coverage.