Top Custom Grinder Manufacturer: Quality and Innovation in Every Grind

Need a custom grinder manufacturer? This guide will help you find reliable partners that produce high-quality, personalized grinders. We’ll discuss key factors like manufacturer experience, production capabilities, and material choices. Make informed decisions for your brand with these insights.

Key Takeaways

Custom grinders enhance brand visibility and customer loyalty through personalization and unique design options.

Choosing an experienced manufacturer ensures quality production and timely delivery of custom grinders to meet business needs.

The materials used in custom grinders, such as aluminum and wood, significantly influence their performance and appeal, catering to diverse user preferences.

The Importance of Custom Grinders

Custom grinders are not just a tool; they are a statement. Custom grinders enable businesses to create unique, recognizable products that significantly enhance brand visibility on shelves. When a customer chooses your grinder over a generic one, they are not just buying a product; they are engaging with your brand. This engagement fosters a deeper emotional connection, turning casual buyers into loyal customers.

The personalization of grinders can significantly boost customer loyalty. Clients appreciate products that reflect their preferences and values, which is why custom herb grinders, featuring designs from minimalist aesthetics to intricate motifs, are so popular. Integrating custom designs allows businesses to cater to specific customer demographics, creating unique experiences and enhancing overall satisfaction.

Quality assurance is a cornerstone in the production of custom grinders. Regular inspections and rigorous testing ensure that each grinder is consistent, durable, and performs to the highest standards. These measures not only guarantee a good quality grinding experience but also ensure that businesses can stay competitive by offering products that meet specific market trends.

Choosing the Right Custom Grinder Manufacturer

Selecting the right manufacturer for your custom grinders is crucial. A manufacturer’s experience in the industry can provide valuable insights into their reliability and expertise. An experienced manufacturer is more likely to understand the nuances of creating high-quality custom grinders, ensuring that your product meets the desired specifications and standards.

Evaluating a manufacturer’s production capacity is equally important. You need to ensure that they can handle your order size and meet your timelines. A manufacturer with adequate production capacity will be able to deliver your custom grinders on time, without compromising on quality. This reliability is essential for maintaining your brand’s reputation and ensuring customer satisfaction.

Materials Used in Custom Grinders

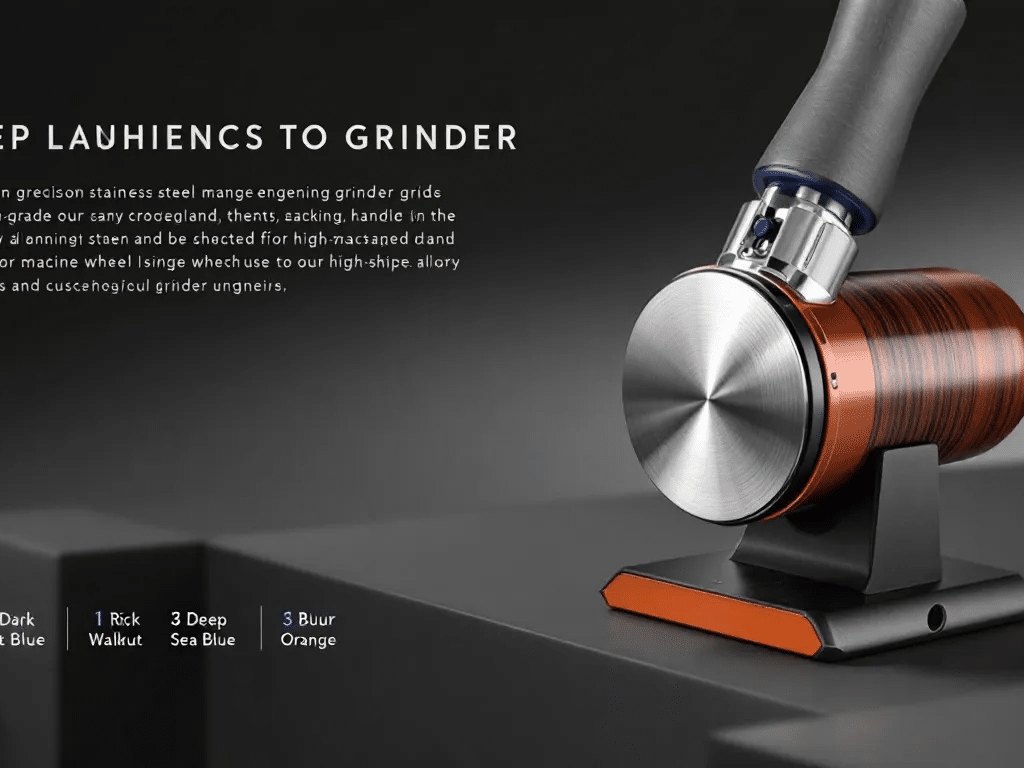

The material of a custom grinder plays a significant role in its performance and appeal. Two primary materials dominate the market: aluminum and wood, each bringing unique advantages suited for different user preferences. Whether you prioritize durability, aesthetic appeal, or a balance of both, understanding the characteristics of these materials can help you make an informed decision.

Aluminum grinders are known for their lightweight nature, affordability, and high durability, making them a preferred choice for many users.

On the other hand, wood grinders offer a visually appealing design and provide a natural feel, appealing to those who favor an organic aesthetic in their smoking accessories.

Aluminum Grinders

Aluminum grinders are a staple in the herb grinding industry. Their lightweight nature and high durability make them ideal for regular use. These grinders are typically crafted with precision, featuring sharp diamond-shaped teeth that efficiently break down dense materials for a smooth grind. The combination of effective tooth shape and arrangement contributes to both the durability and performance of aluminum grinders.

Different teeth configurations can significantly influence the efficiency of the grinder. The arrangement and shape of the teeth determine how finely the material is processed. This precision ensures that users get a consistent grind every time, enhancing their overall experience and satisfaction with the product.

Wood Grinders

Wood grinders, in contrast, offer a warm and organic feel that appeals to many users. These grinders often feature a visually appealing design, making them a favorite among those who appreciate the natural aesthetic and tactile experience. The unique qualities of wood grinders enhance the overall smoking experience, providing a tactile feel that metal grinders cannot match.

Wood grinders appeal to customers who value organic materials and aesthetics, making them a strategic choice for businesses targeting this demographic. The natural appeal of wood not only differentiates your product from the competition but also resonates with customers who prefer eco-friendly products.

Custom Grinder Design Options

Custom grinders offer a plethora of design options that cater to different preferences and business needs. From classic aesthetics to contemporary, modern designs, the possibilities are endless. A manufacturer’s ability to meet specific customization requests is crucial for ensuring the final product aligns with your brand identity.

Whether you want to incorporate logos, images, or intricate patterns, custom grinders can be tailored to reflect your brand’s unique style. This flexibility allows businesses to create products that not only serve a practical purpose but also act as effective branding tools.

Logo and Branding Integration

Incorporating company logos into grinder designs typically involves techniques like laser engraving or screen printing. These methods ensure that the branding elements are durable and visually appealing. Businesses can submit their designs in various formats, including JPG and SVG, to ensure compatibility with manufacturing processes.

Many manufacturers offer a free mockup design service, allowing customers to visualize their logo or design on the grinder before placing an order. This service ensures that all specifications such as dimensions and materials are clearly outlined, providing confidence that the final product will meet expectations.

Custom Teeth Configurations

The teeth configurations in custom grinders play a critical role in determining their grinding efficiency. Aluminum grinders often feature precision diamond-shaped teeth, which enhance their grinding efficiency and effectiveness. These sharp teeth can efficiently break down dense materials, ensuring a smooth and consistent grind.

Customizing the teeth configurations allows businesses to offer grinders that cater to different user preferences and needs. Whether your customers prefer a fine or coarse grind, the right teeth configuration can make all the difference in their grinding experience.

Production Process of Custom Grinders

The production process of custom grinders involves multiple stages, each with stringent quality control measures to ensure the final product’s quality. Transparency in production processes and material sourcing is essential to trust a manufacturer’s commitment to quality. From design submission to the final inspection, each step is meticulously executed to maintain consistency and durability.

Customer satisfaction is a primary focus, ensuring that the custom grinders meet the client’s expectations. By understanding the production process, businesses can better appreciate the craftsmanship and attention to detail that goes into creating each custom grinder.

Design Submission

Businesses can submit their designs through various platforms, ensuring they meet the manufacturer’s technical requirements for production. The production process typically involves several phases, including concept design, prototyping, and final manufacturing. Each stage is crucial for capturing the client’s needs and preferences accurately.

Most custom grinder orders require a minimum quantity for production, often starting at around 50 units. This requirement ensures that the production process is cost-effective while still delivering high-quality products.

Following the design submission process ensures custom grinders truly reflect the brand identity.

Manufacturing and Quality Control

The manufacturing of custom grinders begins with a thorough design process to ensure specifications are met. This process includes material selection, machining, assembly, and finishing. Each stage is carefully executed to maintain consistency in quality.

Quality control measures include inspections at each stage, ensuring that any defects are identified and rectified promptly. Testing procedures are rigorously applied to the finished products to guarantee they meet the highest quality standards. Through comprehensive production and quality control, manufacturers can deliver custom grinders that fulfill customer expectations and elevate brand quality.

Benefits of Custom Grinders for Businesses

Custom grinders serve as effective marketing tools, allowing businesses to enhance brand visibility and recognition among customers. Offering unique custom grinder designs helps businesses differentiate themselves from competitors, creating a unique selling point that attracts more customers.

Examples of successful businesses using custom grinders include Miss Jones, a prominent Canadian dispensary, which expanded its brand by collaborating on custom products like weed grinders and branded ashtrays. Similarly, Lux Pot Shop in Seattle achieved brand differentiation by designing a unique two-piece grinder with intricate laser engravings, fostering greater brand visibility.

These success stories highlight how personalized grinders can foster customer loyalty and act as effective promotional tools.

Case Studies: Success Stories with Custom Grinders

Custom grinders are increasingly used by businesses as promotional products, enhancing brand visibility. Lux Pot Shop, for instance, leveraged custom grinders to foster greater brand visibility with intricate laser engravings. These products not only serve as merchandise but also create additional revenue streams for businesses.

Many businesses have successfully integrated custom grinders into their promotional strategies, leading to increased customer engagement. Seaweed & Co, a leading Maine dispensary, increased brand awareness by ordering 5,000 custom matte grinders in various colors, helping them stand out in a competitive market.

These case studies underscore the potential of custom grinders to transform business outcomes.

How to Order Custom Grinders

The ordering process for custom grinders typically begins with selecting the type of grinder that fits your requirements, considering options such as materials and sizes. Once you’ve chosen your preferred grinder, it’s essential to confirm the order details, including design specifications and delivery timelines, before finalizing the purchase.

Following these steps ensures that the custom grinders meet your expectations and align with your brand identity. The process is straightforward, allowing businesses to efficiently create and receive high-quality custom grinders tailored to their needs.

Summary

Custom grinders offer a unique blend of practicality and branding potential. They enhance brand visibility, foster customer loyalty, and serve as effective marketing tools. By choosing the right manufacturer and understanding the materials and design options available, businesses can create custom grinders that truly reflect their brand’s identity.

The success stories and benefits outlined in this post highlight the transformative potential of custom grinders for businesses. As you consider integrating custom grinders into your promotional strategy, remember that these products are more than just tools; they are powerful instruments for brand growth and customer engagement.

Frequently Asked Questions

What are the primary materials used in custom grinders?

Custom grinders primarily utilize aluminum and wood. Aluminum offers durability and lightness, while wood provides an appealing organic aesthetic.

How can I incorporate my company's logo into a custom grinder design?

To successfully incorporate your company’s logo into a custom grinder design, you can utilize laser engraving or screen printing techniques. Ensure your logo is submitted in compatible formats like JPG or SVG for seamless integration.

What should I consider when choosing a custom grinder manufacturer?

When selecting a custom grinder manufacturer, it is essential to consider their industry experience and production capacity to ensure reliability and meet your order requirements effectively. Prioritizing these factors will facilitate a successful partnership.

What are the benefits of offering custom grinders for my business?

Offering custom grinders significantly enhances brand visibility and fosters customer loyalty, acting as effective promotional tools that differentiate your business from competitors and boost customer engagement.

What is the typical process for ordering custom grinders?

The typical process for ordering custom grinders includes selecting the desired type, confirming design specifications and delivery timelines, and finalizing the purchase. Following these steps ensures a smooth transaction and meets your specific needs.